Production Knowledge Platform

Aufgrund der technischen Terminologie ist der Projektplan in Englisch verfasst.

Status Quo

SEW currently keeps information on production processes, suppliers, and specific equipment in its production lines in a network drive. This information is largely in German, and not easily accessible outside specific teams. For example, colleagues from China can't currently discover this information and use it for their own production line planning.

Goal

The goal is to build a knowledge platform that allows SEW employees to access and query this information in a natural language interface, such as a chat app or web interface. Employees with the right access level can query this interface in their language, and get answers with links to relevant documents and sources.

To facilitate better accessibility, our team will also propose a new structure for the existing documents, and some tooling improvements (such as moving from on-premise drives to Sharepoint Online, or using graph & vector databases).

Personas

Different groups of employees at SEW will use the knowledge platform for different purposes:

- Industrial Engineers: Engineers in all locations of SEW need access information on suppliers, production lines, and equipment to be able to plan new productiom lines

- Procurement: Procurement teams need to access information on suppliers and their products

- Management Power Users: Management wants to access "fully linked" information on production lines, suppliers, and equipment to make strategic decisions

In total there are about 100 employees in these groups.

Approach

Knowledge Structuring and Extraction

A team from Motius first analyzes existing content and develops a strategy for providing a structured knowledge base.

Information will be retrieved from existing sources (network drive, MES, etc.) and processed using RAG. Additional, smaller sources, may be added with MCP (production application APIs such as Vibecheck, or SEW's own fleet management).

| Technology | Data Source | Description |

|---|---|---|

| RAG | Network share, internal documentation, operating manuals | AI-powered search and extraction of relevant information from various sources. Very efficient for searching, but requires dedicated infrastructure |

| MCP | Confluence, CAD systems, ERP, MES | Standardized interface for querying information. Ad hoc, requires very little infrastructure, but is slower than RAG |

Metadata, System & Technology Descriptions

The scope of this project includes a new proposal for how this information should be structured in the stored for easier retrieval in the future. For example, adding more metadata & relationships between documents, storing it in Sharepoint Online and querying it using Microsoft's Graph API, adapting the structure & format of the documents, or adding more data infrastructure such as a graph database or vector database.

The team will also create Systems Description and Technology Description templates for Vibecheck, which can be used to document further systems in the production lines. After Vibecheck, Gear Control could be documented by SEW in the same format.

With the templates, new metadata, and existing metadata (authors, last opened dates, creation dates, folder structure, etc.) there should be enough information to infer relationships between documents, and for an agent to find the latest and most relevant documents.

Note

SEW's IT will need to support the team in setting up a new Sharepoint metadata structure, if necessary in a new Sharepoint Online environment. If these chanegs can't be set up on short notice, the team will mock / simulate new infrastructure and metadata.

Production Data

The plans & suppliers of manufacturing lines may not be useful by themselves, without information on their performance, EoL quality, revisions, and the current state of the line.

To answer questions about performance or quality, the system needs to be able to access data from the MES and ERP systems.

For the PoC, the team will start with quality and order data from the Vibecheck project, to show what kind of queries and insights are possible. Further data sources can be added easily using MCP, if they provide a well-documented API.

Doxis Web

Doxis Web is SEW's document management system, which contains information on almost all business logic in SEW, a lot of which is classified.

We assume that for the PoC phase of the project, documents from Doxis Web will need to be added manually by the user. If possible, documents will be made searchable & accessible through MCP. The latter approach would be a lot more flexible and user-friendly, but requires a green light and some technical support from SEW's IT and security team. Doxis offers a REST API that could be used as a basis for an MCP server.

Rapid Prototyping and Integration

Once the data sources have been reviewed and connected, a prototype is developed using either an on-premise LLM, or a private cloud deployment in Azure (using OpenAI models).

Employees at SEW can start validating the system and provide feedback after 1-2 sprints (each 2 weeks).

For quicker development & deployment, SEW needs to either provide the necessary infrastructure to run a large language model on-premise, or clear a large part of the production knowledge to be used with Azure OpenAI services.

For the PoC, we will use an Azure OpenAI deployment, which is already used by SEW for other AI use cases.

Data Enrichment and Automation

After the first tests, the team adds more data sources and builds first agents that can automate tasks and provide deeper insights for different processes that need access to production data:

- Accessing supplier information for maintenance planning

- Proposing suppliers for new production lines, based on the product that is being produced

- Generating a Systems Description or Technology Description document for Gear Control, based on the Vibecheck project, and existing documents

- Checking new documents for missing metadata, and proposing improvements to the document structure

The PoC will consist of a model that can answer questions about suppliers and production lines, and an agent that can generate Systems Description and Technology Description documents.

Ontologies

The following ontology demonstrates how electric motor production knowledge could be structured to support intelligent queries and analysis:

graph TB

%% Styles

classDef primary fill:none,stroke:#64CEE4,stroke-width:2px,rx:10px

classDef data fill:#E5E5E5,stroke:#888,stroke-width:2px,rx:10px

classDef highlighted fill:#64CEE4

classDef defaultBackground fill:#FFFFFF44,stroke:none,rx:20px

classDef primaryData fill:#64CEE4,stroke:#64CEE4

classDef primaryBackground fill:#23BAD933,stroke:none,rx:20px

subgraph MOTOR_TYPES["Motor Types"]

AC[AC Motors]

DC[DC Motors]

SERVO[Servo Motors]

STEPPER[Stepper Motors]

end

subgraph MOTOR_COMPONENTS["Motor Components"]

STATOR[Stator]

ROTOR[Rotor]

BEARING[Bearings]

WINDING[Windings]

MAGNET[Magnets]

HOUSING[Housing]

ENCODER[Encoder]

BRAKE[Brake]

end

subgraph MANUFACTURING_TECH["Manufacturing Technologies"]

WELD[Welding]

CNC[CNC Machining]

STAMPING[Stamping]

CASTING[Die Casting]

ASSEMBLY[Assembly]

TESTING[Testing]

PAINTING[Painting]

subgraph PRODUCTION_PARAMS["Production Parameters"]

SPEED[Production Speed]

QUALITY[Quality Metrics]

COST[Cost Parameters]

TOLERANCE[Tolerances]

MATERIAL[Material Properties]

end

subgraph SUPPLIERS["Suppliers & Equipment"]

SUPPLIER[Suppliers]

MACHINE[Production Machines]

TOOL[Tooling]

FIXTURE[Fixtures]

end

end

%% Motor type relationships

AC --> STATOR

AC --> ROTOR

DC --> STATOR

DC --> ROTOR

SERVO --> ENCODER

SERVO --> BRAKE

%% Component manufacturing relationships

STATOR --> WINDING

STATOR --> STAMPING

STATOR --> MAGNET

ROTOR --> CASTING

HOUSING --> CNC

HOUSING --> CASTING

BEARING ---> ASSEMBLY

ROTOR --> CNC

%% Manufacturing process relationships

WINDING ---> WELD

CNC --> TOLERANCE

CASTING --> MATERIAL

ASSEMBLY --> TESTING

%% Production relationships

WELD --> MACHINE

CNC --> TOOL

STAMPING --> FIXTURE

ASSEMBLY --> SUPPLIER

STAMPING --> QUALITY

%% Quality and cost relationships

COST --> SUPPLIER

SPEED --> MACHINE

TOLERANCE --> TOOL

%% Styling

classDef motorType stroke:#0288d1,stroke-width:2px,fill:none

classDef component stroke:#7b1fa2,stroke-width:2px,fill:none

classDef manufacturing stroke:#ef6c00,stroke-width:2px,fill:none

classDef parameter stroke:#388e3c,stroke-width:2px,fill:none

classDef resource stroke:#c2185b,stroke-width:2px,fill:none

class AC,DC,SERVO,STEPPER motorType

class STATOR,ROTOR,BEARING,HOUSING,WINDING,MAGNET,ENCODER,BRAKE component

class WELD,CNC,STAMPING,CASTING,ASSEMBLY,TESTING,PAINTING manufacturing

class SPEED,QUALITY,COST,TOLERANCE,MATERIAL parameter

class SUPPLIER,MACHINE,TOOL,FIXTURE resource

class MOTOR_TYPES,MOTOR_COMPONENTS,MANUFACTURING_TECH primaryBackground

class PRODUCTION_PARAMS,SUPPLIERS defaultBackgroundThis ontology enables structured queries like:

- "Which suppliers provide bearings for servo motors?"

- "What CNC machining tolerances are required for DC motor housings?"

- "Show me welding procedures for stator windings in AC motors"

- "Compare quality metrics between stamped and cast rotor components"

Whether these relationships can be established in the PoC phase depends on the data available in the existing documents. The aim is to give the model enough context to understand the relationships between different components, or to suggest changes to the document structure to make these relationships more explicit. For the latter case, the team will mock or simulate the relationships in the data for a smaller set of documents.

Architecture

Since other AI usecases within SEW already use Azure OpenAI for internal applications, we recommend using Azure OpenAI for the PoC. new open-weight models, such as GPT OSS, could be used for the Production Knowledge Hub but would require more time to set up and test, than the state-of-the-art models available in Azure OpenAI.

Azure

Azure's OpenAI services provide a powerful platform for building AI assistants and agents:

- Azure OpenAI Service for scalable LLM hosting and integration

- Azure AI Foundry portal and the ingestion API for data integration and management

- MCP for tool calling and integration with existing systems

We've also worked with Azure Data factory and Microsoft Fabric for data integration and management. These wouldn't be necessary for the PoC, but could be used to stay consistent & compatible with other SEW deployments.

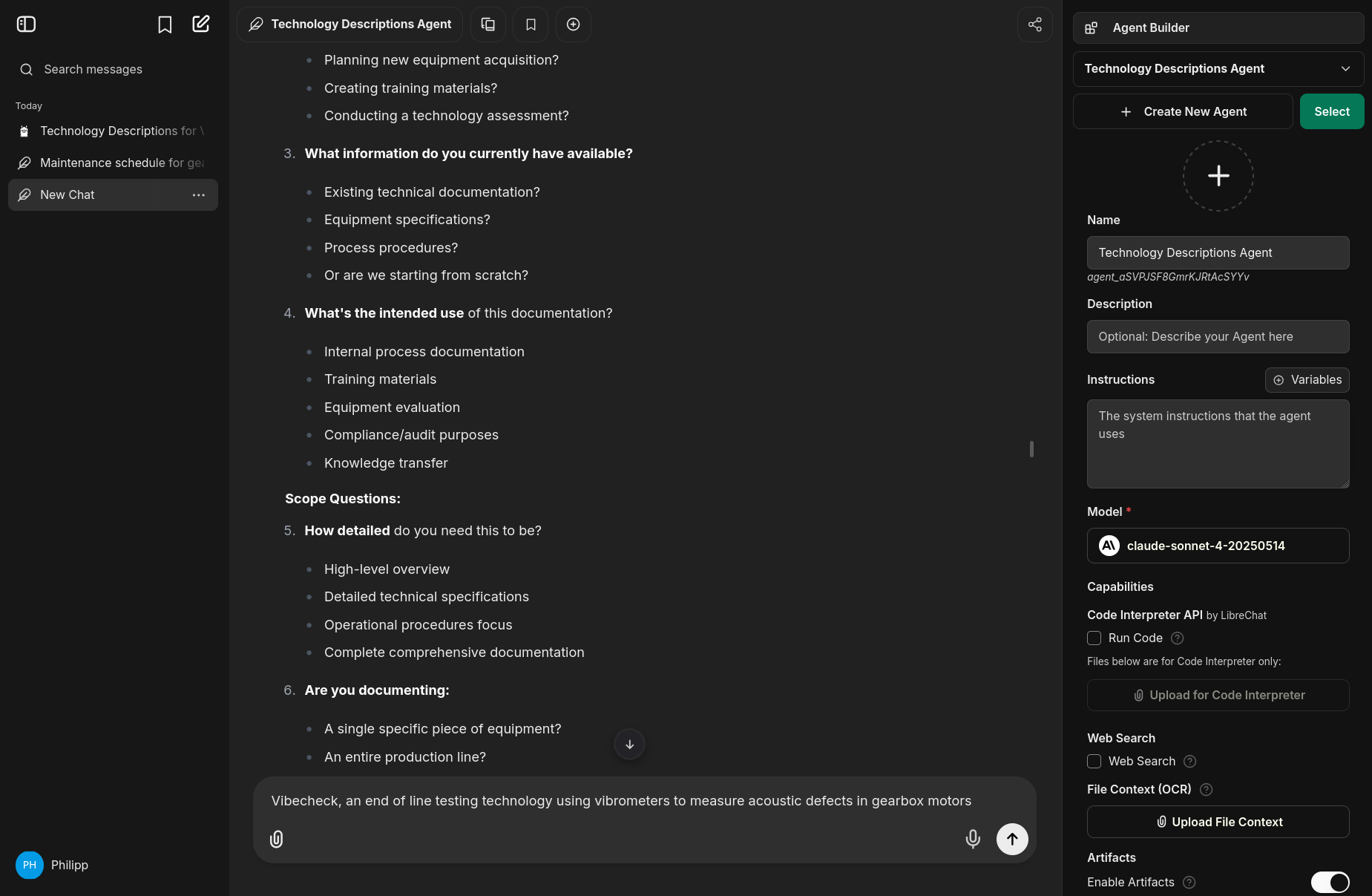

On-Premise

We deploy a mix of open source components and open-weight LLM models for on-premise deployments:

- LibreChat is an extensible chat interface with built-in support for all common LLMs, including open source models like Meta's Llama, Google DeepMind's Gemma, or GPT OSS

- PostgreSQL with pgvector for vector storage and as a simple data warehouse

- MCP for tool calling and integration with existing systems

graph TB

%% Styles

classDef primary fill:none,stroke:#64CEE4,stroke-width:2px,rx:10px

classDef data fill:#E5E5E5,stroke:#888,stroke-width:2px,rx:10px

classDef highlighted fill:#64CEE4

classDef defaultBackground fill:#FFFFFF44,stroke:none,rx:20px

classDef primaryData fill:#64CEE4,stroke:#64CEE4

classDef primaryBackground fill:#23BAD933,stroke:none,rx:20px

subgraph SS ["Source Systems"]

ERP[(ERP)]

CRM[(CRM)]

EXT[(External Data)]

FILES[(Share Drive)]

SHAREPOINT[(Sharepoint Online)]

end

subgraph DP ["Azure Private Cloud"]

subgraph STORAGE ["Storage"]

RAW[(Raw)]

CLEANSED[(Cleansed)]

ENRICHED[(Enriched)]

CURATED[(Curated)]

end

subgraph SPECIALIZED ["Specialized Storage"]

VECTOR[(Vector DB)]

GRAPH[(Graph DB)]

DWH[(Data Warehouse)]

end

subgraph COMPUTE ["RAG"]

INGEST[Ingest]

PARSE[Parse/Chunk/Filter]

EMBED[LLM Model Embedding]

end

subgraph CLOUD_AI ["Azure OpenAI Services"]

SIMILARITY[Similarity Matching]

LLM_GEN[LLM Model Generative]

LLM_EMB[LLM Model Embedding]

end

end

subgraph CUSTOMER ["Knowledge Hub"]

INFO_QUERY[Information Querying]

UI[Chat Interface]

CHAT_HIST[(Chat History)]

subgraph SEW_IT ["SEW IT Infrastructure"]

DASHBOARDS[Reporting Dashboards]

ERP_APP[ERP]

CRM_APP[CRM]

end

end

%% Data Flow

ERP --> RAW

CRM --> RAW

SHAREPOINT --> RAW

EXT --> RAW

FILES --> RAW

RAW --> CLEANSED

CLEANSED --> ENRICHED

ENRICHED --> CURATED

EMBED --> VECTOR

CURATED --> VECTOR

CURATED --> GRAPH

CURATED --> DWH

%% Compute Flow

RAW --> INGEST

INGEST --> PARSE

PARSE --> EMBED

%% Application Layer Connections

VECTOR --> SIMILARITY

SIMILARITY --> LLM_EMB

LLM_EMB --> INFO_QUERY

INFO_QUERY --> UI

UI --> CHAT_HIST

LLM_GEN --> INFO_QUERY

UI --> DASHBOARDS

UI --> ERP_APP

UI --> CRM_APP

%% Styling

classDef sourceSystem stroke:#0288d1,fill:none,stroke-width:2px

classDef dataStorage stroke:#7b1fa2,fill:none,stroke-width:2px

classDef compute stroke:#ef6c00,fill:none,stroke-width:2px

classDef application stroke:#388e3c,fill:none,stroke-width:2px

classDef specialized stroke:#c2185b,fill:none,stroke-width:2px

classDef sew_it stroke:#f57c00,fill:none,stroke-width:2px

class ERP,CRM,SHAREPOINT,EXT,FILES sourceSystem

class RAW,CLEANSED,ENRICHED,CURATED dataStorage

class INGEST,PARSE,EMBED,SIMILARITY,LLM_GEN,LLM_EMB compute

class UI,INFO_QUERY application

class DASHBOARDS,ERP_APP,CRM_APP sew_it

class VECTOR,GRAPH,DWH,CHAT_HIST specialized

class SS,DP,CUSTOMER primaryBackground

class STORAGE,SPECIALIZED,COMPUTE,SEW_IT,CLOUD_AI defaultBackground

Key Features of the Knowledge Platform

The Production Knowledge Hub is designed to be flexible and extensible:

-

On-Premise or Cloud

Our approach works on-premise or using a cloud-based AI model in Azure or AWS. We use open-source components to stay flexible and avoid vendor lock-in, while using the state of the art in AI and LLMs.

-

AI-Powered Assistant

The production AI assistant is capable of understanding and processing natural language queries, providing intelligent responses and insights based on the data it has access to. It seamlessly works with different input languages in SEW's data.

-

Data Integration

Using MCP and RAG we ensure that the AI model has access to the most relevant data, without spending months preparing and cleaning it.

-

Speed & Quick Iterations

With powerful open-source components and state of te art models, Motius only needs a few weeks to set up the infrastructure and first use cases for SEW. From there, we can quickly iterate on data sources and new use cases.

User Experience

LibreChat is an open-source chat interface, that supports all necessary technologies for a PoC, and can query any popular LLM, including cloud and on-premise deployments.

The Motius team can quickly develop agents, that use MCP and tool-calling to access data from SEW's systems, and generate new documents. Performance of different models can be measured just by switching the model in the UI, and rerunning the same queries.

SEW's employees can use the chat interface to ask questions about production lines, suppliers, and equipment, and get answers with links to relevant documents and sources. With support from SEW's IT, the team can also set up SSO and user management, so employees can sign in with their SEW accounts.

Prior Work from Motius

Gandalv is an internal product we built to showcase our approach, and help us during the requirements engineering phase of our projects.

It features similar RAG & MCP capabilities, to make knowledge accessible and provide structure output (in this case, project plans & requirements).

Requirements

requirementDiagram

requirement functional_requirements {

id: 1

text: Functional Requirements

risk: high

verifymethod: test

}

requirement natural_language_query {

id: 1.1

text: Natural Language Query Interface

risk: medium

verifymethod: test

}

requirement multilingual_support {

id: 1.2

text: "Multi-language Support (German/Chinese/English)"

risk: medium

verifymethod: test

}

requirement document_search {

id: 1.3

text: Intelligent Document Search & Retrieval

risk: high

verifymethod: test

}

requirement supplier_information {

id: 1.4

text: Supplier Information Access

risk: medium

verifymethod: test

}

designConstraint production_data_integration {

id: 1.5

text: Production Data Integration (MES/ERP)

risk: medium

}

requirement document_generation {

id: 1.6

text: Automated Document Generation

risk: medium

verifymethod: test

}

requirement non_functional_requirements {

id: 2

text: "Non-Functional Requirements"

risk: high

verifymethod: test

}

requirement security_access_control {

id: 2.1

text: Security & Access Control

risk: high

verifymethod: test

}

designConstraint scalability {

id: 2.2

text: Scalability to many concurrent users

risk: low

verifymethod: test

}

requirement deployment_flexibility {

id: 2.3

text: "On-Premise or Cloud Deployment"

risk: low

verifymethod: demonstration

}

requirement data_privacy {

id: 2.4

text: Data Privacy & Compliance

risk: high

verifymethod: inspection

}

requirement response_time {

id: 2.5

text: "Response Time < 5 seconds"

risk: medium

verifymethod: test

}

requirement system_integration {

id: 3

text: System Integration Requirements

risk: high

verifymethod: test

}

designConstraint sharepoint_integration {

id: 3.1

text: SharePoint Online Integration

risk: medium

}

requirement drive_integration {

id: 3.11

text: "On-Premise Drive Integration"

risk: high

verifymethod: test

}

designConstraint mes_integration {

id: 3.2

text: MES System Integration

risk: high

}

designConstraint erp_integration {

id: 3.3

text: ERP System Integration

risk: high

}

requirement manual_doxis_integration {

id: 3.4

text: Manual Doxis Web Integration

risk: low

verifymethod: test

}

designConstraint mcp_doxis_integration {

id: 3.41

text: MCP Doxis Web Integration

risk: high

}

requirement sso_integration {

id: 3.5

text: SSO Integration

risk: medium

verifymethod: test

}

functional_requirements - contains -> natural_language_query

functional_requirements - contains -> multilingual_support

functional_requirements - contains -> document_search

functional_requirements - contains -> supplier_information

functional_requirements - contains -> production_data_integration

functional_requirements - contains -> document_generation

non_functional_requirements - contains -> security_access_control

non_functional_requirements - contains -> scalability

non_functional_requirements - contains -> deployment_flexibility

non_functional_requirements - contains -> data_privacy

non_functional_requirements - contains -> response_time

system_integration - contains -> drive_integration

system_integration - contains -> mes_integration

system_integration - contains -> erp_integration

system_integration - contains -> manual_doxis_integration

manual_doxis_integration - derives -> mcp_doxis_integration

system_integration - contains -> sso_integration

drive_integration - derives -> sharepoint_integration

natural_language_query - derives -> document_search

multilingual_support - derives -> natural_language_query

supplier_information - derives -> production_data_integration

document_generation - derives -> document_search

security_access_control - derives -> sso_integration

scalability - derives -> deployment_flexibilityRequirements are split into functional, non-functional, and system integration requirements:

- Functional requirements describe the core functionality

- Non-functional requirements describe the quality attributes of the system, such as security, scalability, and performance

- System integration requirements describe how the system will integrate with existing systems and data sources. These require support from SEW's IT and security teams

Design Constraints are not part of the implementation, but need to be considered during the design & architecture phase. For example, MES data integration will be necessary in the future, but not part of the PoC.

Some requirements are high risk:

| Requirement | Explanation |

|---|---|

| Intelligent Document Search & Retrieval | Complex data sources and unstructured documents make reliable search challenging. |

| Security & Access Control | Sensitive production data requires robust access management and compliance, and support from SEW's IT and security teams, who may have additional requirements for the architecture of the system. |

| Data Privacy & Compliance | Handling confidential information must meet strict legal and company policies. |

| On-Premise Drive Integration | Accessing and synchronizing on-premise data sources can be difficult, they often offer less modern APIs than cloud hosted file storage. |

| MES System Integration | MES systems are highly customized and integration may require significant IT support. |

| ERP System Integration | Similar to MES system integration. |

| MCP Doxis Web Integration | Doxis Web contains classified data; integration needs security and technical clearance. |

Work packages

| Work Package | Duration |

|---|---|

| Prepare knowledge structuring & extraction | 5 Days |

| Set up infrastructure in SEW Azure cloud environment | 10 Days |

| Conduct interviews with SEW production and IT experts | 2 Days |

| Design a test strategy for the first use cases | 2 Days |

| Structure & extract data from SEW network drives and documentation systems | 10 Days |

| Create a Systems Description template based on the Vibecheck project | 2 Days |

| Create a Technology Description template based on the Vibecheck project | 2 Days |

| Develop Systems & Technology Agent for Gear Control | 3 Days |

| Develop an MCP server for production & quality data from the Vibecheck project | 2 Days |

| Evaluate cloud LLM models (Azure OpenAI GPT, Anthropic Claude) | 10 Days |

| Develop validation and data quality tools | 10 Days |

| Test knowledge sharing usecases in different languages, for different workflows (querying, planning, maintenance) | 8 Days |

| Identify improvements for document storage (missing metadata, relationships, etc.) and create a proposal for a new document structure | 3 Days |

| Iterate document pipeline, metadata, and agent setup after testing | 5 Days |

| Prepare final report and presentation | 2 Days |

| Meetings, Project Management, and Coordination | 9 Days |

| Total Duration | 85 Days |

Rollen und Kosten

Rollen, Kosten, und der rechtliche Rahmen sind wieder in Deutsch verfasst.

| Rolle | Level | Tagessatz | Tage | Gesamtkosten |

|---|---|---|---|---|

| AI Engineer | Technology Specialist IV | 1,120.00 € | 33.00 Tage | 36,960.00 € |

| Software Engineer | Technology Specialist IV | 1,120.00 € | 31.00 Tage | 34,720.00 € |

| Project Owner | Project Management IV | 1,344.00 € | 19.00 Tage | 25,536.00 € |

| Gesamtkosten Netto | 97,216.00 € | |||

| Steuer (19%) | 18,471.04 € | |||

| Gesamtkosten Brutto | 115,687.04 € | |||

Rate Card

Es gilt die Rate Card aus dem Rahmenvertrag, Stand 2025:

| Bereich | Titel | Level | Stundensatz | Tagessatz |

|---|---|---|---|---|

| Technology Specialist | Senior Lead Tech Specialist | Technology Specialist VI | 180.00 € | 1,440.00 € |

| Lead Tech Specialist | Technology Specialist V | 161.00 € | 1,288.00 € | |

| Senior Tech Specialist | Technology Specialist IV | 140.00 € | 1,120.00 € | |

| Tech Specialist | Technology Specialist III | 126.00 € | 1,008.00 € | |

| Associate Tech Specialist | Technology Specialist III | 112.00 € | 896.00 € | |

| Developer | Technology Specialist I | 84.00 € | 672.00 € | |

| Project Management | Partner | Project Management VI | 230.00 € | 1,840.00 € |

| Senior Technical Executive | Project Management V | 187.00 € | 1,496.00 € | |

| Technical Executive | Project Management IV | 168.00 € | 1,344.00 € | |

| Senior Project Owner | Project Management III | 149.00 € | 1,192.00 € | |

| Project Owner | Project Management II | 133.00 € | 1,064.00 € | |

| Associate Project Owner | Project Management I | 112.00 € | 896.00 € |

Die oben skizzierten Projektrollen stellen ein Referenzteam dar. Sollte es bei der Besetzung der Projektrollen zu Abweichungen kommen, gilt folgende Rate Card. Das Projektvolumen bleibt unberührt.